Concept

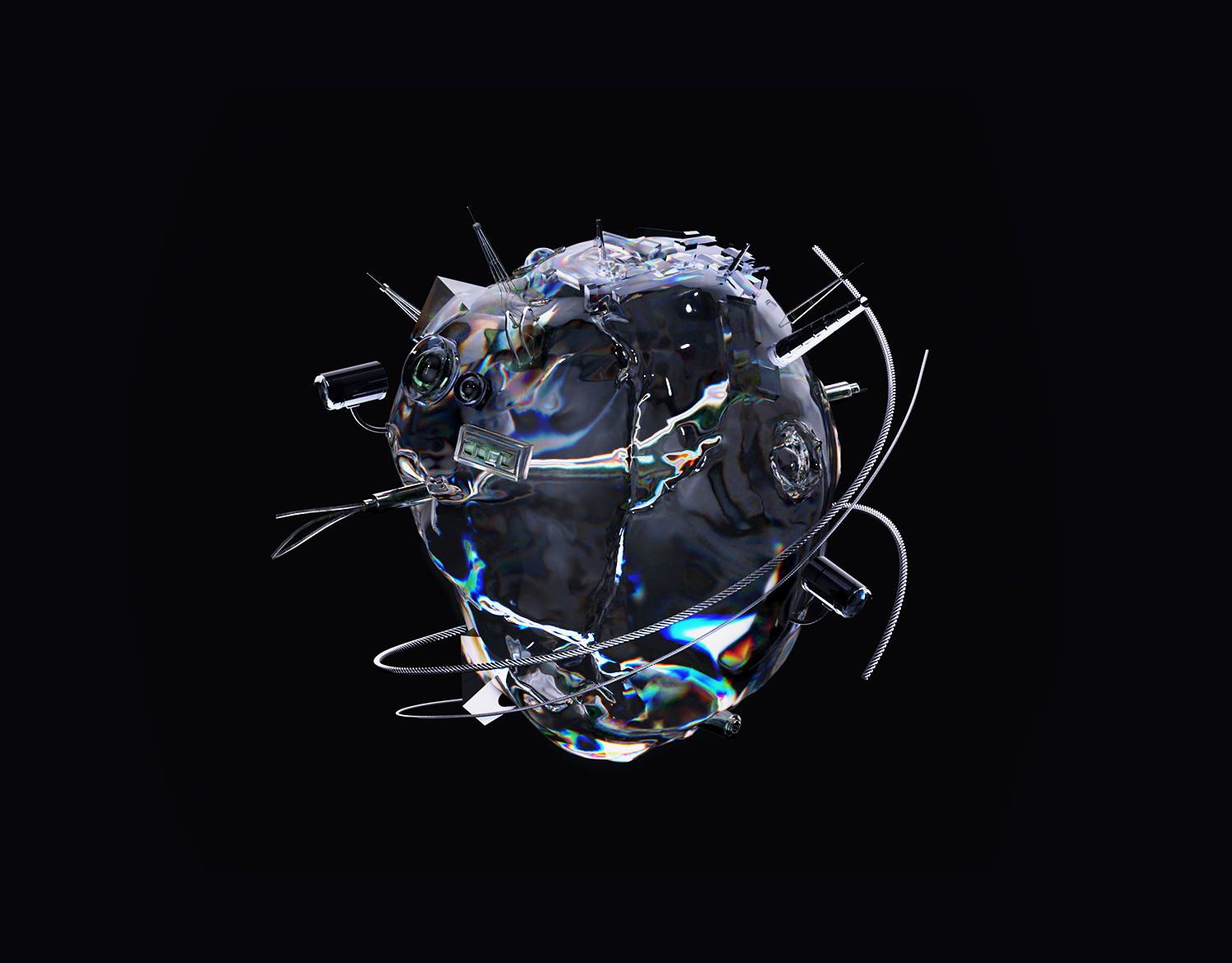

Hypoxia is a common characteristic of the Baltic Sea. In a yearly cycle of algae bloom, death, and decomposition the water is depleted of oxygen forming a notoriously vast dead zone. Oxygen crawlers are a speculative oxygen station for aquatic ecosystems challenging the techno-optimistic notion of technology eventually solving man-made environmental damage.

Hypoxia is a common characteristic of the Baltic Sea. In a yearly cycle of algae bloom, death, and decomposition the water is depleted of oxygen forming a notoriously vast dead zone. Oxygen crawlers are a speculative oxygen station for aquatic ecosystems challenging the techno-optimistic notion of technology eventually solving man-made environmental damage.

Production

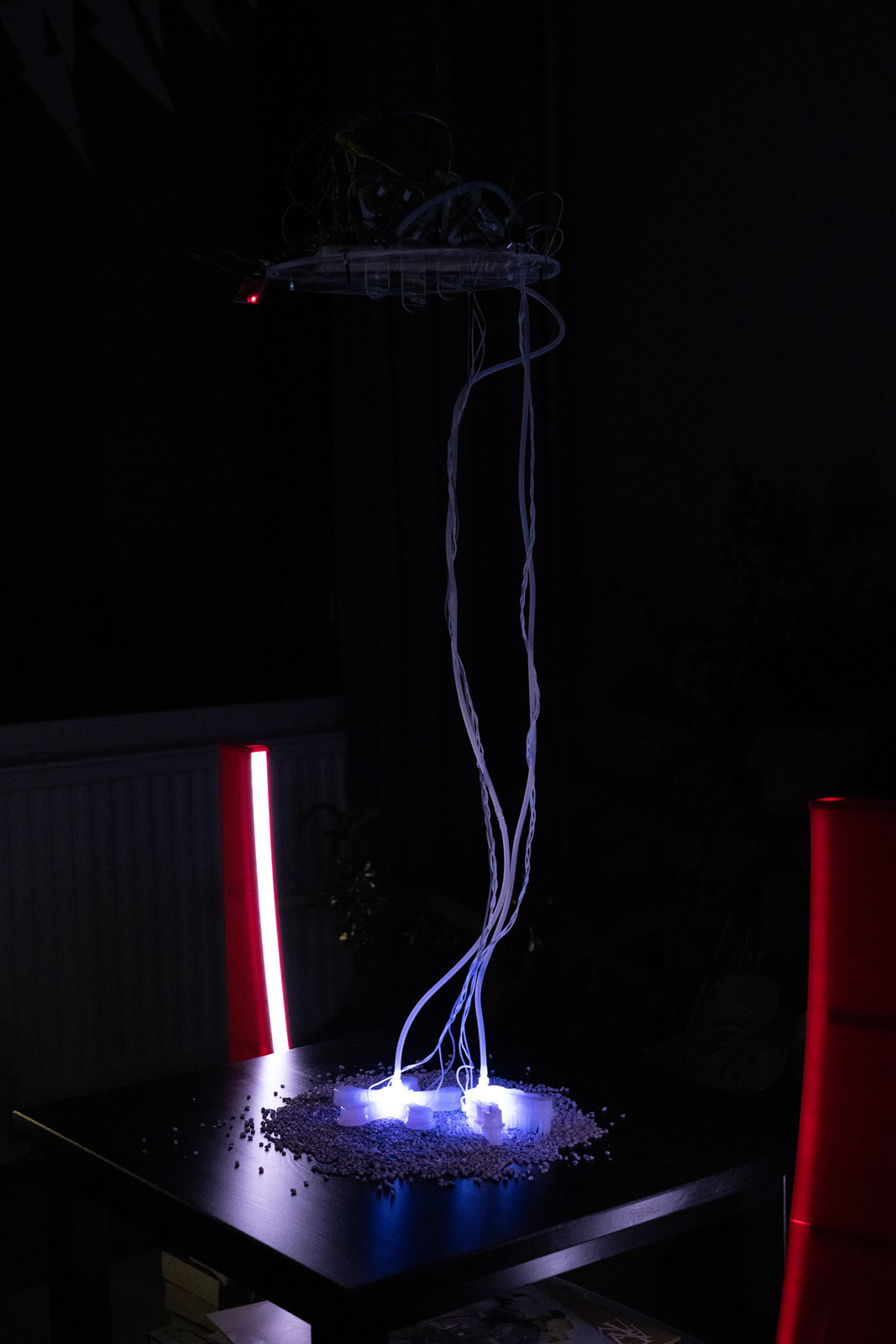

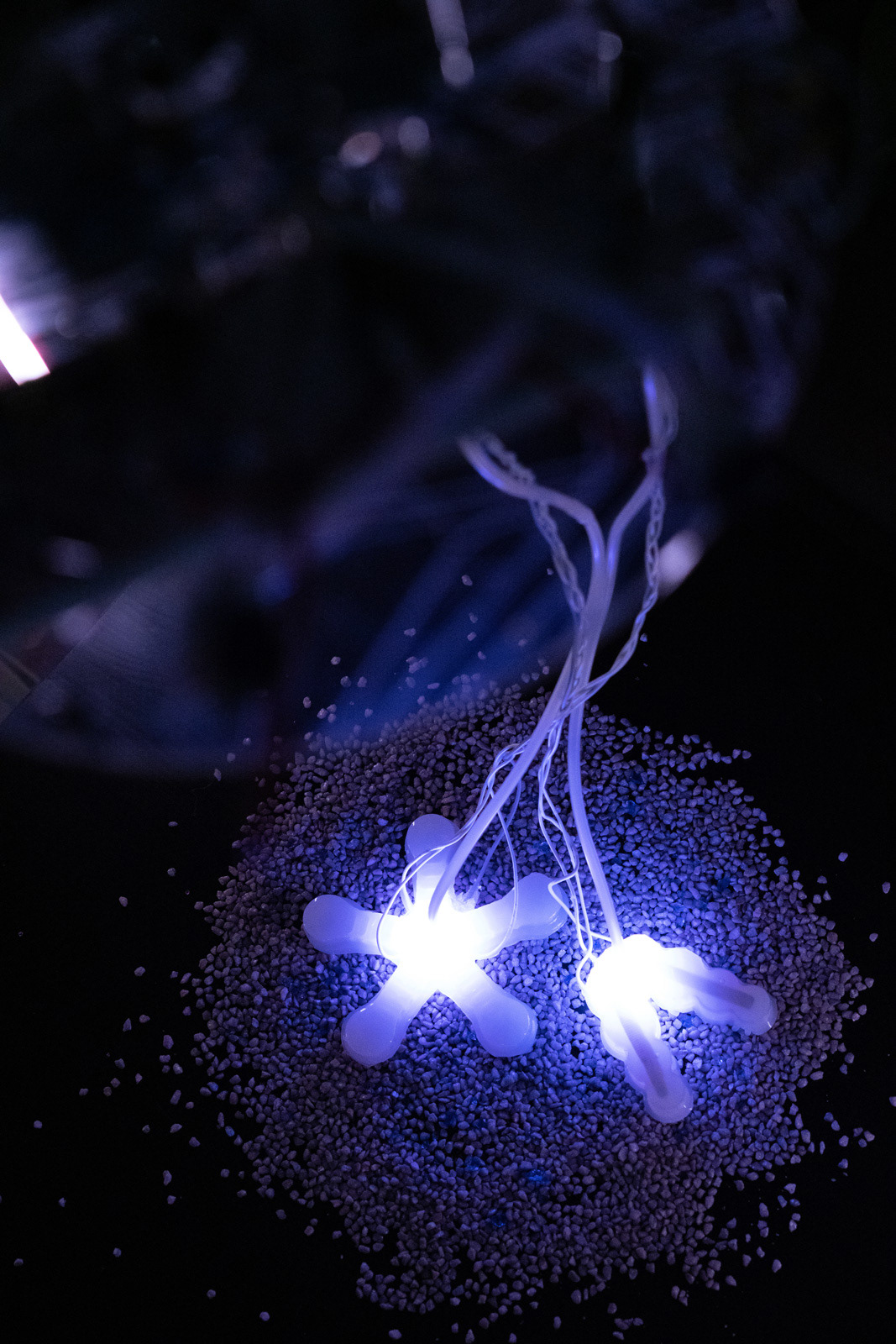

The station consists of a disc hanging from the ceiling (or floating on the water) where all the electronics are stationed; and two types of silicone inflatables/actuators connected with silicone tubing and wires for single LEDs.

Parts:

1x Arduino Uno with a Qwiic shield

2x Air Pump and Vacuum DC Motor - 4.5 V and 2.5 LPM

2x 6V Air Valve with 2-pin JST PH Connector

1x Sparkfun Distance Sensor, VL53L1X

1x Adafruit MPRLS Pressure Sensor

Individual NeoPixel 5050 RGB LEDs

Silicone Tubing, 3mm

Connectors for tubing

Transistors, capacitors, resistors, etc.

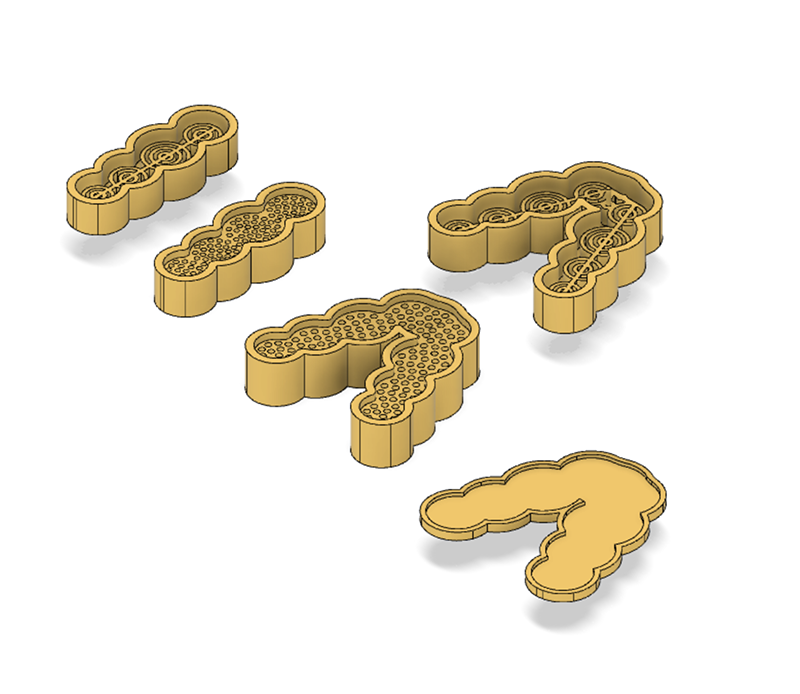

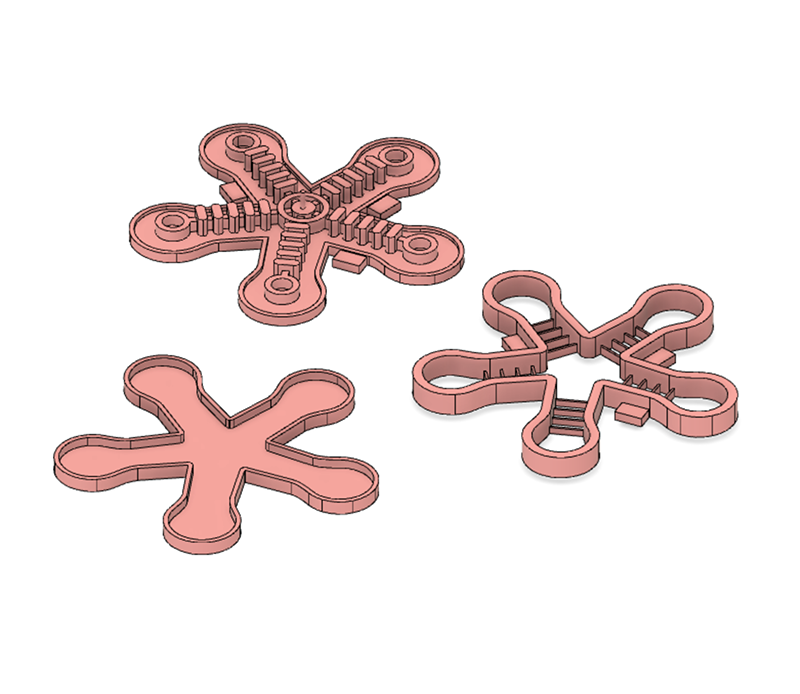

2 silicone actuators (from 3D printed molds)

Disc with screw holes+pump holder (laser cut)

2x Air Pump and Vacuum DC Motor - 4.5 V and 2.5 LPM

2x 6V Air Valve with 2-pin JST PH Connector

1x Sparkfun Distance Sensor, VL53L1X

1x Adafruit MPRLS Pressure Sensor

Individual NeoPixel 5050 RGB LEDs

Silicone Tubing, 3mm

Connectors for tubing

Transistors, capacitors, resistors, etc.

2 silicone actuators (from 3D printed molds)

Disc with screw holes+pump holder (laser cut)

Notes on working with silicone

The silicone used: Smooth-On Ecoflex with shore factors 00-30 and 00-50. Final models made of the 00-50.

Actuators are first made in separate parts, which are then cured and “glued” together with the same silicone mix. In this case, I also inserted a single Neopixel LED with wiring and then glued the pieces, which turned out problematic a few times but not always.

Actuators are first made in separate parts, which are then cured and “glued” together with the same silicone mix. In this case, I also inserted a single Neopixel LED with wiring and then glued the pieces, which turned out problematic a few times but not always.

The availability of the vacuum chamber to extract air bubbles from the rubber increased the endurance, and kitchen-made actuators broke more easily at random points when under pressure.

The starfish model would be better as a two-piece (not a three-piece) mold – the small size of cavities and walls made it more fragile without any benefits.

Models were made in sizes fitting the Ultimaker 2 printer, but ideally, they should be a bit bigger with thicker walls of the final piece.

The two-piece bottom system of the algae model allowed the creation of nice fringes – when pouring the silicone, the two are loosely fit to let the air out, and when the holes are filled with the rubber, the two pieces are locked together.